New contactless levitation system moves delicate components with high precisionAamir Khollam

Interesting EngineeringTue, August 12, 2025 at 7:12 PM EDT

3 min read

Transporting miniaturized components with speed and precision remains a persistent challenge for industries operating at microscopic scales. Friction from conveyor belts, rollers, and other mechanical systems slows movement and limits accuracy.

This is especially problematic for delicate parts in mechanical, chemical, and biomedical applications, where even minor vibrations can cause damage.

To address this, researchers at Yokohama National University have created an untethered levitation device that moves freely in any direction without touching a surface.

Frictionless movement with acoustic levitationThe device relies on acoustic levitation, which uses sound waves to suspend objects in mid-air.

This avoids the size and complexity of magnetic levitation systems that require large magnets or pneumatic setups that depend on pressurized gas.

Both alternatives can be costly, heavy, and unsuitable for portable or compact applications.

Conventional acoustic levitation platforms also have a limitation: cables. These are used to provide power and control, but they interfere with positioning, particularly in precision manufacturing.

"While acoustic levitation removes floor friction, conventional systems rely on cables that disturb positioning," said Ohmi Fuchiwaki, associate professor and researcher at Yokohama National University.

"We solved this by developing an untethered levitation device with a wireless drive circuit, enabling stable levitation height and high-speed, flexible transport."

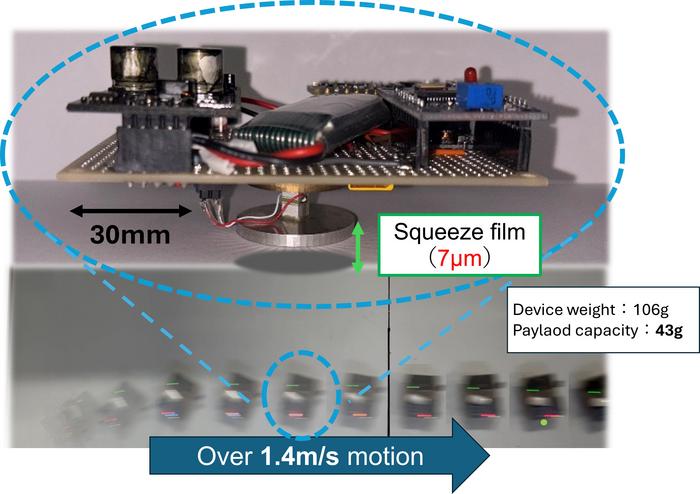

This device achieves frictionless movement on various flat surfaces, enabling high-speed omnidirectional mobility. Credit - YOKOHAMA National University

This device achieves frictionless movement on various flat surfaces, enabling high-speed omnidirectional mobility. Credit - YOKOHAMA National UniversityPerformance tests confirmed the system’s potential. The device moved at speeds exceeding three meters per second on an inclined surface.

At a slope of 10°, it glided freely when levitation was active but could not overcome gravity when switched off. These results demonstrated that the friction problem had been successfully addressed.

The researchers also examined payload capacity.

The device maintained smooth motion while carrying up to 150 grams in total, allowing around 43 grams for the payload itself. Any weight beyond that stopped levitation and movement entirely.

Compact design with omnidirectional motionA piezoelectric actuator drives the system, generating a squeeze film, a thin fluid layer between two surfaces, to enable omnidirectional movement. This allows the platform to navigate with agility in any direction without physical contact.

The compact, centimeter-scale design makes it suitable for use in confined spaces. Applications could include assembling tiny electronics, transporting chemical samples in sterile environments, or moving biomedical cells without physical handling.

The absence of contact reduces contamination risks, a major advantage in sensitive operations.

The experimental results matched theoretical predictions, reinforcing the system’s viability. Researchers believe that its speed, maneuverability, and lack of tethers could allow deployment in settings that demand both precision and cleanliness.

Looking ahead, the team aims to link multiple levitation units with a propulsion mechanism to create mobile robots for contactless delivery.

Such a system could navigate factory floors, laboratories, or medical facilities without touching surfaces.

Plans also include improving levitation efficiency, increasing load stability, and adapting the design for uneven terrain.

Achieving these goals could broaden its reach beyond controlled lab conditions into mainstream industrial use.

The findings have been published in the journal Advanced Intelligent Systems.

https://www.yahoo.com/news/articles/contactless-levitation-system-moves-delicate-231244535.html

![]() 6 new categories and 72 new items added to the shop!

6 new categories and 72 new items added to the shop!![]() 6 new categories and 72 new items added to the shop!

6 new categories and 72 new items added to the shop!

Select your theme

Select your theme